Review - SKIL Flooring Saw

With most tool reviews, there’s a baseline for evaluating the qualities of a tool – an established set of expectations and performance criteria for that particular class of tool. In this case, however, there is no such baseline. Skil effectively invented a new class and category of tool when they introduced their Flooring Saw (model 3600-02). At the time of this review, there was no equivalent-but-competitive version to measure it against. (Although another consumer brand tool manufacturer has since released their own flooring saw, this writer has yet to put hands on it.)

So, being virtually the only tool in the category, I suppose it’s safe to award the 3600-02 “Best in Class” honors without virtue of even unpacking the box. But that still begs the question of whether there’s even a need for this new category of tool and, if so, how well this lone entrant meets that need.

I’ve heard from at least one other tool writer that I respect (he’ll remain nameless because I fear him as much as I respect him and he writes for ToolSkool, also), that there’s absolutely no need for this tool. It doesn’t do anything that you can’t already do with a miter saw and a table saw – that is, rip to width and cut to length hardwood and laminate flooring materials.I submit that his argument against the tool is equally strong in favor of it. One tool that fills the role of two? Sounds good to me - especially for homeowners and DIYers who aren’t already equipped with a miter saw and table saw. If the choice is buy one tool or buy two tools, it seems an easy one to make. And the economy of the question goes beyond what you’d pay for one saw versus two; there’s also the question of space and size.

If space and size sound like the same thing, they aren’t. When I say space, I mean where do you plan to put these tools when you’re done with your flooring project. By size I mean which choice (flooring saw vs. miter and table saw) is more likely to fit into the room where you’re doing the work? On both questions, the flooring saw has the advantage. It’s compact and lightweight enough to take it to the work and then store it away on a shelf, in the rafters, or hanging on a wall when the work is through.

Of course, it’s a pretty solid tenet that any tool designed to fill too many roles probably isn’t ideal in any of them (Swiss Army Knives being the obvious exception). And, to a degree, that principle has some merit here. The Skil Flooring Saw is neither an exceptional miter saw nor a table saw – not the engineers at Skil ever intended that it should be. Because while it’s tempting to think of this as a miter/table saw surrogate, it is in fact, a highly specialized tool that, in fact, has only one function: to cut flooring material.

Thus, the saw has to be measured solely on its ability to make big flooring pieces smaller. And on that score, it excels.

Anatomy of a Flooring Saw

Having spent all this time and text to compare and contrast the Flooring Saw to a miter saw and table saw, now seems the perfect time to muddy the waters even further and introduce another tool the Flooring Saw is not – a tile saw.

I bring this up because the flooring saw looks and operates a lot like a tile saw. (Note: As much as it may look like one, it isn’t one. So don’t try to cut tile with it. I won’t be held responsible for the damages if you do. I’m pretty sure the folks at Skil are with me on this.)

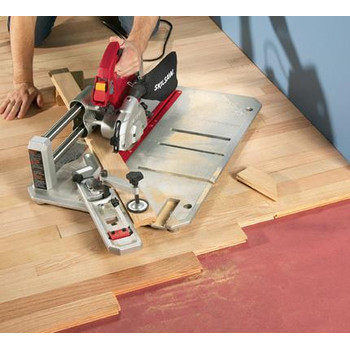

The saw itself is mounted to rails which are attached to an aluminum base. An adjustable fence can be set for ripping or crosscutting. And depending on which cut you’re performing, the saw is either stationary (ripping) or glides along the rails (crosscutting). The saw is powered by a 7-amp motor which turns a 4-3/8”, 40-tooth carbide-tipped blade. Weighing in at just 25 lbs., the saw is easy to transport. Onboard cord storage and stowable push stick keep things organized for the move. A dust collection bag, blade wrench, and material hold-down clamp are also standard fare.

Flooring Saw in Action

Comparisons and categories aside, what ultimately matters is whether this saw works well in its intended role. So I took it to work with me on a small laminate install to find out.

As I mentioned before, the saw is compact and lightweight. Both virtues for this basement installation because I was able to set the saw up in the room where the floor was being installed. That probably saved me close to a mile of trekking back and forth between the worksite and the driveway, which is where I would’ve been forced to park a miter saw and table saw.

And because I would be making all of the flooring cuts inside the house, I opted for a shop vacuum attached to the dust collection port in lieu of the dust bag. Apart from occasionally having to fuss with the vacuum hose to keep it out of the way of a cut, this proved to be a good choice as there was very little dust to clean up at the end of the day.

Throughout the project, the saw proved its worth and answered any doubts I had about the need for and viability of a specialized flooring saw. The saw powered through laminate flooring easily – which is to be expected. But I also took the opportunity to rip and crosscut a few pieces of solid oak flooring. And while the saw didn’t handle these with the ease of table saw, I never felt like the saw was underpowered for the task.

One thing I need to mention here is that the saw is loud. That’s thanks to its 11,000 rpm grinder motor. I can only guess that Skil went with this motor over a quieter, slower, albeit larger, circular saw motor in the interest of keeping the tool as small and lightweight as possible.

Although the argument can be made that they selected this motor as a way to ensure quality cuts. The combination of a small-diameter, high-tooth-count blade turning at 11,000 rpm (motor speed) provided consistently smooth cuts with no evidence of tear out or splintering during my project. So, whatever their reasoning, Skil got it right with the power plant on the flooring saw. The teeth-rattling whine of the motor is a small price to pay for clean cuts.

Conclusion

So, in answer to the question “Does the world really need a dedicated flooring saw?” my answer is a resounding yes. Even if you already own a miter saw and table saw, the merits of this tool are more than enough to justify the $150 to $180 price it’s currently selling for on tool websites. You can find it on Amazon.com for $158. Relative to what you’re likely to spend on quality laminate or hardwood flooring, the saw is a bargain for convenience and ease-of-use it brings to a high-impact home improvement project.